Types

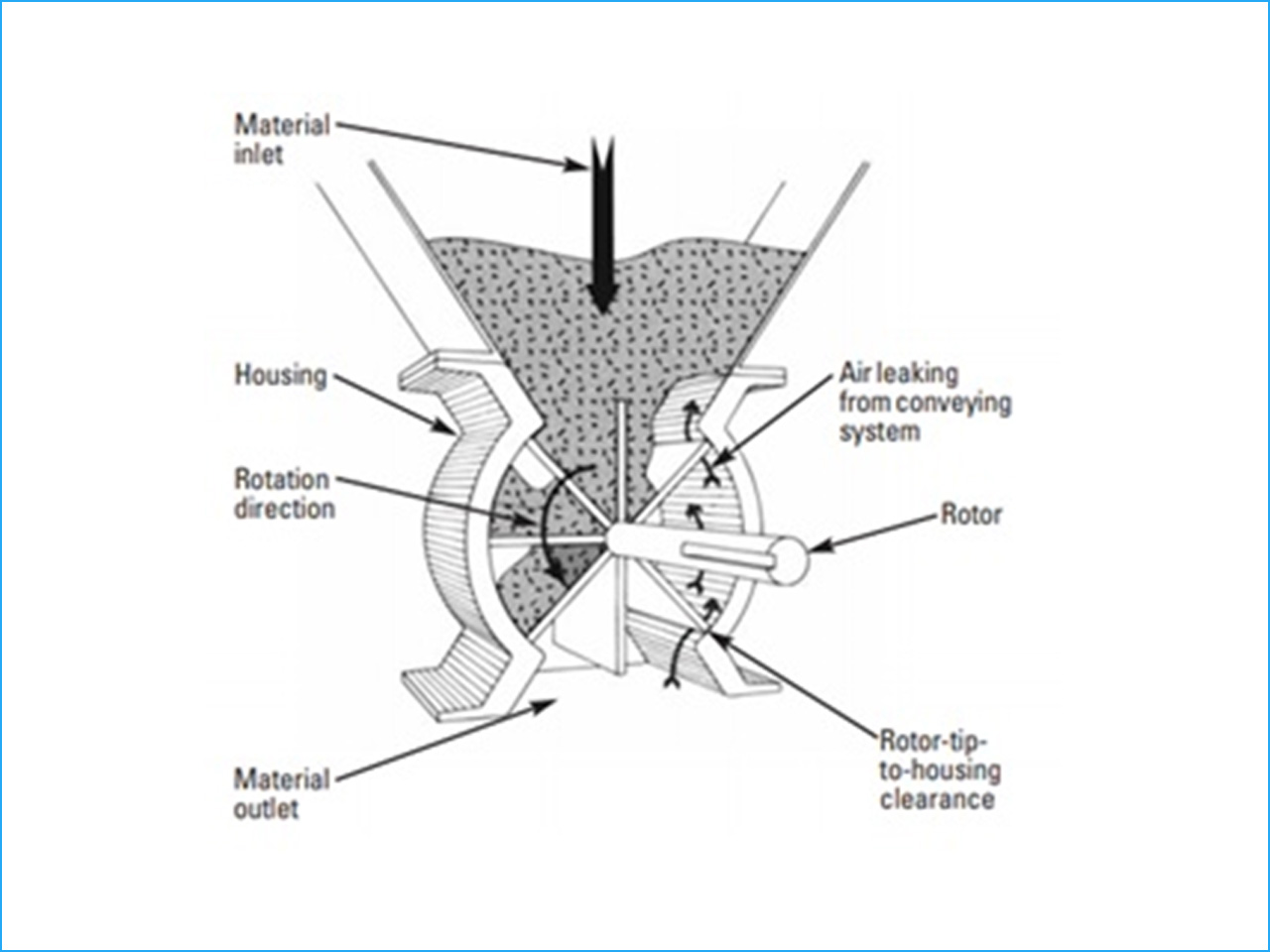

Rotary airlock

The basic use of the rotary airlock feeder is as an airlock transition point, sealing pressurized systems against loss of air or gas while maintaining a flow of material between components with different pressure and suitable for air lock applications ranging from gravity discharge of filters, rotary valves, cyclone dust collectors, and rotary airlock storage devices to precision feeders for dilute phase and continuous dense phase pneumatic convey systems

Rotary valve

Rotary airlock feeders/ rotary airlock valves are used in pneumatic conveying systems, dust control equipment, and as volumetric feed-controls.

Volumetric feeder

Rotary airlock valves are also widely used as volumetric feeders for metering materials at precise flow rates from bins, hoppers, or silos onto conveying or processing systems.